sikotec – 3P® Plus Shortliner Process

The sikotec – 3P® Plus Shortliner process is a sewer spot repair method that allows for the sectional, low cost and trenchless (without need to excavate the sewer pipe) and remote repair of sewer/underground pipes. This long-lasting solution is eco-audit certified and approved by the German Institute of Civil Engineering (DIBt) Z-42.3-326 till 01.01.2021.

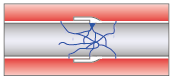

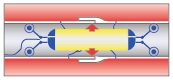

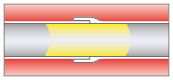

After determine the exact damaged area a resin-saturated fiberglass laminate is placed at the repair site using a repair bladder. Sliding rods or a lifting jack and a surveillance camera are typically used to position it accurately. The repair bladder is inflated and the laminate pressed against the inside wall of the sewer pipe, forcing the excess resin into the damaged area for a long-lasting seal. After about a two-hour curing period the repair bladder is removed and full leak-tightness is restored: the liner creates a “pipe-in-pipe system”.

This process is ideal for the repair of cracks, leaky pipe connections, blocked blind connections, root in-growth…..

The material can be used for the restoration of almost every type of sewer/underground pipes with a cross section of 100 to 700 mm in diameter.

If you have any questions, please do not hesitate to contact us.

sikotec® GmbH

Robert-Bosch-Straße 28

D – 88131 Lindau

Phone: +49 (0) 8382 / 97 53 23

Fax: +49 (0) 8382 / 97 53 25

Email: infoservice@sikotec-gmbh.de

Internet: www.sikotec-gmbh.de

Sikotec GmbH was founded in 1994 with work on security and conference technology.

In addition to security systems (alarm and video surveillance), Sikotec GmbH started the sales & distribution of synthetic resin used in sewer pipe spot repair in 1996.

Sikotec GmbH also provides technical support for gated parking lots in the city of Lindau as well as the ticket vending machines on city busses.